Featured image for are there water ballast on cruise line ships

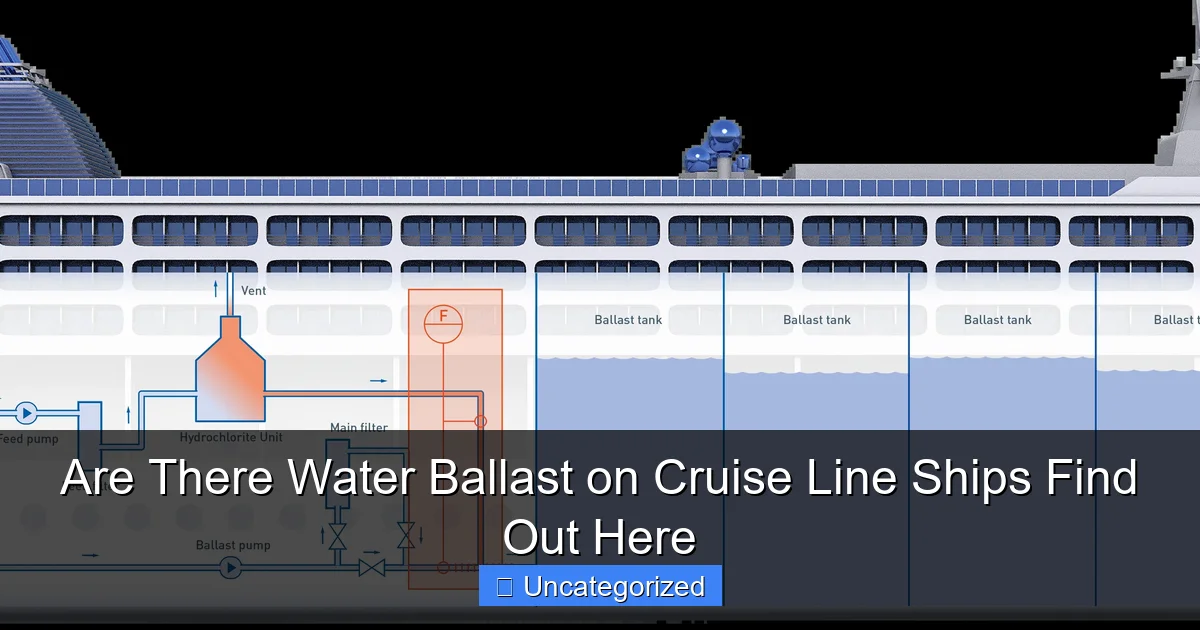

Image source: dam.krohne.com

Yes, cruise ships use water ballast systems to maintain stability and balance when passenger loads, cargo, or fuel levels shift during voyages. These tanks, filled with seawater, adjust weight distribution to ensure safe, smooth sailing—critical for handling rough seas and preventing capsizing.

Key Takeaways

- Water ballasts are essential for stability and safety on cruise ships.

- Modern systems are eco-friendly, minimizing environmental impact during ballasting.

- Regulations govern ballast use to prevent invasive species spread.

- Ballast tanks adjust dynamically for optimal balance during voyages.

- Excess water is filtered and treated before ocean discharge.

- Ballast capacity varies by ship size and design needs.

- Proper maintenance prevents leaks and ensures operational efficiency.

📑 Table of Contents

- Are There Water Ballast on Cruise Line Ships? Find Out Here

- What Are Water Ballast Systems and How Do They Work?

- Why Cruise Ships Rely on Water Ballast: Stability and Safety

- Environmental Concerns and Ballast Water Treatment

- Innovation and the Future of Ballast Systems on Cruise Ships

- Case Studies: Ballast Systems in Action on Major Cruise Ships

- Conclusion: The Vital Role of Water Ballast in Modern Cruising

Are There Water Ballast on Cruise Line Ships? Find Out Here

When you picture a luxury cruise liner gliding across the ocean, you might imagine gleaming decks, gourmet dining, and breathtaking ocean views. But beneath the surface of these floating cities lies a complex engineering system that ensures stability, safety, and efficiency. One of the most critical yet often overlooked components of modern cruise ship design is the water ballast system. If you’ve ever wondered, “Are there water ballast on cruise line ships?”—the answer is a resounding yes. These systems are not just present; they’re essential to the ship’s operation, performance, and environmental compliance.

Water ballast systems have been a cornerstone of maritime engineering for centuries, but their role has evolved dramatically with modern technology, environmental regulations, and the sheer size of today’s cruise vessels. From the Harmony of the Seas to the Queen Mary 2, every major cruise line employs sophisticated water ballast systems to maintain balance, control trim and draft, and meet international safety standards. In this comprehensive guide, we’ll dive deep into how these systems work, why they’re crucial for cruise ships, and what innovations are shaping their future. Whether you’re a maritime enthusiast, a future cruiser, or simply curious about the inner workings of giant ocean liners, this article will answer all your questions—and perhaps raise a few more.

What Are Water Ballast Systems and How Do They Work?

Definition and Core Function

A water ballast system is a network of tanks, pumps, pipes, and valves designed to intake, store, and discharge seawater to adjust a ship’s weight distribution. The primary purpose is to maintain stability by controlling the vessel’s center of gravity, trim (fore-aft balance), and draft (how deep the ship sits in the water). Without ballast, a ship—especially one that’s partially loaded or empty—would be dangerously unstable, prone to rolling, pitching, or even capsizing in rough seas.

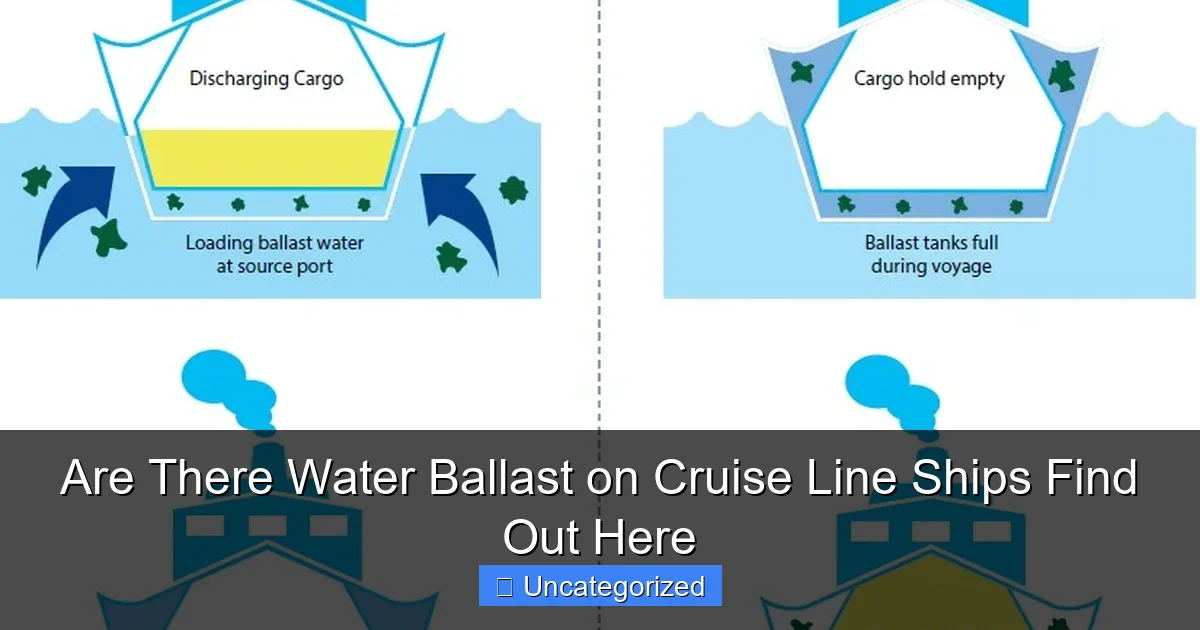

Visual guide about are there water ballast on cruise line ships

Image source: marinestudy.net

For cruise ships, which carry thousands of passengers and crew, along with massive amounts of fuel, food, and supplies, balance is critical. As passengers move around the ship, fuel is consumed, and supplies are used, the weight distribution changes. The ballast system compensates for these shifts in real time. For example, when a ship departs a port with full fuel tanks and a full passenger load, it may not need much ballast. But after days at sea, as fuel is burned, the ship becomes lighter and higher in the water. The ballast system then pumps in seawater to compensate, keeping the vessel stable and seaworthy.

How the System Operates

The operation of a water ballast system is both mechanical and automated. Here’s a step-by-step breakdown:

- Intake: Seawater is drawn through sea chests (openings in the hull below the waterline) using powerful ballast pumps.

- Distribution: The water is routed through a network of pipes to ballast tanks located in the double-bottom, wing tanks, and fore/aft peak tanks.

- Monitoring: Sensors and computer systems continuously monitor the water level in each tank, ship trim, draft, and stability metrics.

- Discharge: When ballast water is no longer needed (e.g., at the next port), it is pumped back into the sea using the same pumps.

- Control: Modern cruise ships use integrated control systems that automatically adjust ballast based on real-time data, reducing human error.

For example, the Carnival Horizon uses an automated ballast control system that interfaces with the ship’s navigation and stability software. If the system detects a slight list to port due to uneven passenger movement, it can automatically transfer ballast water from starboard to port tanks in seconds. This level of precision ensures a smooth, safe ride even in challenging sea conditions.

Why Cruise Ships Rely on Water Ballast: Stability and Safety

Maintaining Dynamic Stability

Stability is the cornerstone of maritime safety, and cruise ships face unique challenges. Unlike cargo vessels, which carry consistent loads, cruise ships experience dynamic weight fluctuations throughout a voyage. Passengers move from deck to deck, dining rooms are full at certain hours, and tenders (small boats) are loaded and unloaded during excursions. All of these activities affect the ship’s center of gravity.

Visual guide about are there water ballast on cruise line ships

Image source: 1.bp.blogspot.com

The ballast system acts as a dynamic counterbalance. For instance, during a port call in Nassau, the Norwegian Escape may offload 200 passengers via tenders and load 300 new ones. This sudden shift in weight distribution could destabilize the ship if not corrected. The ballast system responds by adjusting water levels in the bow and stern tanks to maintain a level trim. Without this capability, the ship could develop a dangerous list (tilt) or even capsize in extreme cases.

Controlling Draft and Trim

Draft—the depth of the ship below the waterline—is crucial for safe navigation, especially in shallow ports or narrow channels. Cruise lines often operate in areas like the Caribbean, where many ports have limited depth. By adjusting ballast, the ship can reduce its draft to enter shallow harbors. For example, the MSC Meraviglia can reduce its draft by up to 1.5 meters by discharging ballast water, allowing it to dock at smaller ports that larger vessels cannot access.

Trim—the balance between the bow and stern—also affects fuel efficiency and maneuverability. A ship that is too bow-heavy will plow through waves, increasing resistance and fuel consumption. Conversely, a stern-heavy ship may struggle to steer. The ballast system ensures optimal trim, improving performance and reducing emissions. Royal Caribbean’s Icon of the Seas, for instance, uses AI-powered ballast algorithms to maintain ideal trim throughout the voyage, saving an estimated 3–5% in fuel costs.

Emergency Situations and Damage Control

In rare but critical scenarios—such as hull breaches or flooding—the ballast system can be repurposed for emergency stabilization. By flooding specific ballast tanks, the crew can counteract flooding in damaged compartments, preventing capsizing. This technique is known as counter-flooding and has saved vessels in the past. While modern cruise ships are designed with watertight compartments to prevent flooding, the ballast system remains a vital backup tool for damage control.

Environmental Concerns and Ballast Water Treatment

The Invasive Species Problem

While water ballast systems are essential for safety, they’ve long been associated with a major environmental issue: biological pollution. When ships take in ballast water in one region and discharge it in another, they can transfer non-native species such as algae, bacteria, mussels, and even small fish. These invasive species can wreak havoc on local ecosystems, outcompete native species, and damage infrastructure. For example, the zebra mussel, introduced to the Great Lakes via ballast water, has caused billions in damage to water intake systems and native habitats.

Cruise ships, which often follow fixed itineraries and visit the same ports repeatedly, are significant contributors to this problem. A single large cruise ship can carry up to 2,000 tons of ballast water, potentially containing millions of organisms. This has led to growing international concern and strict regulatory measures.

International Ballast Water Management Regulations

In 2004, the International Maritime Organization (IMO) adopted the Ballast Water Management Convention (BWMC), which entered into force in 2017. This treaty requires all ships over 400 gross tons (which includes every major cruise ship) to:

- Install and operate a Ballast Water Treatment System (BWTS)

- Maintain a Ballast Water Management Plan (BWMP)

- Conduct regular inspections and reporting

- Exchange or treat ballast water in open ocean (at least 200 nautical miles from shore and in waters deeper than 200 meters)

Failure to comply can result in heavy fines, detention, or denial of port entry. As a result, cruise lines have invested hundreds of millions of dollars in retrofitting and upgrading their ballast systems.

Modern Ballast Water Treatment Technologies

Today’s cruise ships use advanced treatment systems to eliminate or neutralize organisms in ballast water. Common technologies include:

- Filtration + UV Radiation: Removes large particles and kills microorganisms with ultraviolet light. Used on ships like Celebrity Edge.

- Electrochlorination: Uses electric current to generate chlorine from seawater, killing bacteria and viruses. Found on Princess Cruises’ Sky Princess.

- Deoxygenation: Deprives organisms of oxygen by injecting inert gases. Used in conjunction with other methods.

- Chemical Treatment: Adds biocides (e.g., chlorine dioxide), though this is less common due to environmental concerns.

These systems are not only effective but also energy-efficient and automated, requiring minimal crew intervention. For example, the Holland America Line’s Nieuw Statendam uses a UV-based system that treats 1,500 cubic meters of water per hour, ensuring compliance while maintaining operational efficiency.

Innovation and the Future of Ballast Systems on Cruise Ships

Smart Ballast Systems with AI and IoT

The future of water ballast on cruise ships lies in digitalization and automation. Modern vessels are increasingly equipped with smart systems that integrate ballast control with navigation, propulsion, and environmental monitoring. These systems use AI algorithms to predict ballast needs based on weather forecasts, passenger load, and itinerary changes.

For instance, the Royal Caribbean’s Oasis-class ships use a centralized “Shipboard Automation System” (SAS) that connects ballast pumps, sensors, and navigation data. If the system detects an approaching storm, it can proactively adjust ballast to lower the ship’s center of gravity, improving stability in high waves. Similarly, IoT-enabled sensors monitor water quality in ballast tanks, ensuring treatment systems are working effectively and reducing the risk of non-compliance.

Alternative Ballast Methods and Research

While seawater remains the most practical and cost-effective ballast, researchers and engineers are exploring alternatives to reduce environmental impact:

- Solid Ballast: Using non-toxic, non-leaching materials like sand or gravel. While heavier and less flexible, it eliminates the need for water treatment. Still in experimental stages.

- Air-Based Systems: Using compressed air in sealed tanks to displace water. Requires significant energy and is not yet viable for large ships.

- Closed-Loop Systems: Treating and reusing ballast water without discharge. Challenges include space and energy requirements.

One promising innovation is the “ballast-free” hull design, being tested in some cargo vessels. These ships use internal water circulation to maintain stability without carrying large volumes of ballast. While not yet practical for cruise ships due to their size and complexity, the technology may evolve in the coming decades.

Green Shipping Initiatives and Industry Leadership

Cruise lines are also investing in green ballast practices as part of broader sustainability goals. For example:

- Carnival Corporation has committed to treating 100% of its ballast water by 2025, exceeding IMO requirements.

- MSC Cruises uses a hybrid UV/electrochlorination system that reduces energy use by 30% compared to traditional methods.

- Norwegian Cruise Line has partnered with ballast treatment manufacturers to develop smaller, more efficient systems for retrofitting older ships.

These efforts not only reduce environmental impact but also enhance the cruise line’s public image and compliance with ESG (Environmental, Social, and Governance) standards.

Case Studies: Ballast Systems in Action on Major Cruise Ships

To understand the real-world application of water ballast systems, let’s examine three leading cruise ships and how their ballast systems contribute to safety, efficiency, and sustainability.

Royal Caribbean’s Symphony of the Seas

- Ballast Capacity: 12,000 metric tons

- System Type: Automated, UV-based treatment with AI trim optimization

- Key Features: Real-time stability monitoring, predictive ballast adjustment, and integration with the ship’s dynamic positioning system

- Environmental Impact: Treats 99.9% of organisms in ballast water; reduces fuel consumption by 4% through optimal trim

Celebrity Cruises’ Celebrity Beyond

- Ballast Capacity: 8,500 metric tons

- System Type: Filtration + UV + deoxygenation

- Key Features: IoT sensors for water quality, automated reporting for compliance, and energy-efficient pumps

- Environmental Impact: Zero discharge in sensitive marine areas; uses renewable energy to power treatment systems

Holland America Line’s Koningsdam

- Ballast Capacity: 7,200 metric tons

- System Type: Electrochlorination with remote monitoring

- Key Features: Remote diagnostics, predictive maintenance, and integration with the ship’s environmental management system

- Environmental Impact: 99.8% organism removal; complies with all U.S. Coast Guard and IMO standards

Data Table: Ballast System Comparison Across Cruise Lines

| Ship | Ballast Capacity (tons) | Treatment Method | Automation Level | Compliance | Environmental Efficiency |

|---|---|---|---|---|---|

| Symphony of the Seas | 12,000 | UV + AI Optimization | High (Fully Automated) | IMO, USCG | 4% fuel savings |

| Celebrity Beyond | 8,500 | Filtration + UV + Deoxygenation | High | IMO, EU | Renewable-powered |

| Koningsdam | 7,200 | Electrochlorination | Medium-High | IMO, USCG | 99.8% organism removal |

| Norwegian Encore | 9,100 | UV + Filtration | High | IMO, USCG | Low energy consumption |

| MSC Grandiosa | 10,500 | Hybrid UV/Electrochlorination | High | IMO, EU | 30% energy reduction |

This data illustrates the diversity and sophistication of modern ballast systems across the cruise industry, reflecting both technological advancement and environmental responsibility.

Conclusion: The Vital Role of Water Ballast in Modern Cruising

So, are there water ballast on cruise line ships? Absolutely—and they are far more than just tanks of seawater. These systems are the unsung heroes of maritime engineering, ensuring that the world’s largest floating resorts remain stable, efficient, and environmentally responsible. From maintaining dynamic balance amid shifting passenger loads to complying with stringent international regulations, water ballast systems are integral to the safe and sustainable operation of every major cruise ship.

As the cruise industry continues to grow and evolve, so too will ballast technology. Innovations in AI, IoT, and green treatment methods are transforming ballast systems from a necessary evil into a model of eco-conscious engineering. The future may even see ballast-free designs or closed-loop systems that eliminate discharge entirely. But for now, the humble water ballast remains a cornerstone of cruise ship safety and performance.

The next time you board a cruise ship, take a moment to appreciate the invisible network of pipes, pumps, and sensors working silently below deck. It’s not just about comfort—it’s about science, safety, and sustainability. And now, you know exactly how it works.

Frequently Asked Questions

Are there water ballast systems on cruise line ships?

Yes, modern cruise ships use water ballast systems to maintain stability and balance when passenger loads, cargo, or fuel levels change. These tanks are strategically placed to adjust the ship’s center of gravity during voyages.

How do water ballast tanks work on cruise ships?

Water ballast tanks are filled or emptied to compensate for weight distribution, ensuring the ship remains level and safe in rough seas. This process helps optimize fuel efficiency and passenger comfort during travel.

Why do cruise ships need water ballast?

Cruise ships require water ballast to counteract uneven weight from passengers, luggage, or fuel consumption. Without it, the vessel could become unstable, risking safety and comfort.

Is water ballast on cruise ships environmentally safe?

Modern cruise lines follow strict regulations to minimize environmental impact, including treating ballast water to prevent invasive species transfer. Systems like UV filtration or chemical treatment are often used to comply with international standards.

Where are water ballast tanks located on a cruise ship?

Water ballast tanks are typically built into the lower hull or along the sides of the ship. Their placement ensures optimal weight distribution and stability during navigation.

Do all cruise line ships use water ballast systems?

Yes, nearly all large cruise ships use water ballast systems as a standard safety measure. Smaller vessels or specialized ships may use alternative stabilization methods, but ballast remains the most common solution.