Featured image for how much does a cruise liner cost to make

Image source: thepointsguy.global.ssl.fastly.net

Building a modern cruise liner can cost between $500 million to over $1.5 billion, depending on size, luxury features, and shipyard location. High-end amenities, advanced propulsion systems, and custom interiors significantly drive up expenses, with some mega-ships surpassing 200,000 gross tons. These floating resorts represent massive investments, often taking 3–5 years from design to launch.

Key Takeaways

- Costs range from $500M to $1B+ for modern cruise liners, depending on size and luxury.

- Labor and materials dominate expenses, with steel, tech, and skilled craftsmanship driving up prices.

- Customization adds significant cost—themed interiors, pools, and theaters increase budgets quickly.

- Regulatory compliance is non-negotiable—safety, emissions, and design standards impact final pricing.

- Long-term maintenance is costly—budget for upkeep, repairs, and dry-dock refurbishments early.

- Shipyard location affects pricing—Asian builders often offer lower costs than European rivals.

📑 Table of Contents

- How Much Does a Cruise Liner Cost to Make Revealed

- Understanding the Basics: What Makes Up the Cost of a Cruise Liner?

- Breaking Down the Cost by Ship Size and Class

- The Role of Shipyards and Location in Pricing

- Hidden Costs You Might Not Think About

- Real-World Examples: Case Studies of Cruise Liner Costs

- Data Table: Cruise Liner Cost Comparison (2020–2024)

- Final Thoughts: The True Cost of a Floating City

How Much Does a Cruise Liner Cost to Make Revealed

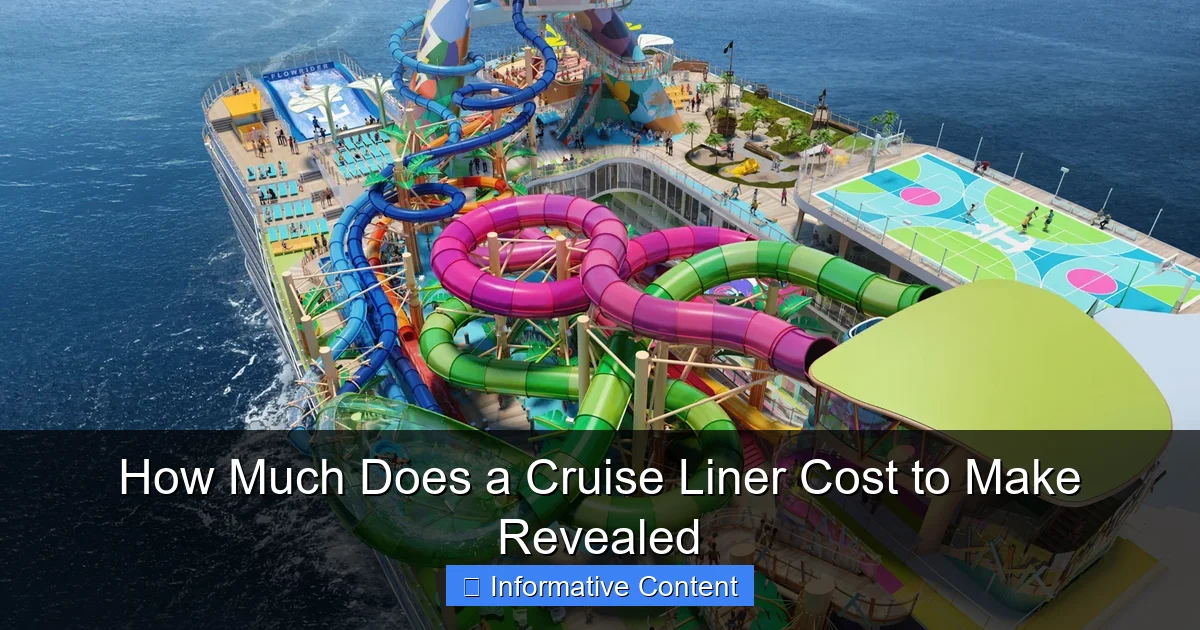

Imagine walking into a floating city. You step aboard a vessel that’s longer than three football fields, with towering decks, endless dining options, and even a zip line. This isn’t a fantasy—it’s the reality of modern cruise liners. These engineering marvels are among the most complex and expensive machines humans build. But how much does a cruise liner cost to make? It’s not just about the steel and labor. It’s about luxury, safety, sustainability, and pushing the limits of what’s possible on the open sea.

As someone who’s spent years researching maritime engineering and tourism trends, I’ve always been fascinated by the behind-the-scenes of cruise ship construction. I remember visiting a shipyard in Finland years ago, standing next to a hull that was still under construction. The sheer scale was overwhelming. Workers in hard hats moved like ants across a structure that would one day carry 6,000 guests. That moment sparked my curiosity: What goes into building something this massive? And more importantly, how much does it really cost? In this post, we’ll break it down—no jargon, no fluff—just honest answers to one of the most asked questions in the cruise industry.

Understanding the Basics: What Makes Up the Cost of a Cruise Liner?

To answer the question, how much does a cruise liner cost to make, you first need to understand what you’re actually paying for. A cruise ship isn’t just a boat with a few cabins. It’s a floating ecosystem. Think of it like building a 20-story hotel, a power plant, a waste management facility, and a theme park—all on water, and all designed to move at 20+ knots.

Visual guide about how much does a cruise liner cost to make

Image source: tffn.net

Core Components That Drive the Price

- Hull and Structure: This is the backbone—steel, welding, and design. The hull alone can account for 20–25% of total costs. Modern ships use high-tensile steel to save weight and fuel.

- Propulsion Systems: Engines, generators, and fuel tanks. Today’s ships often use diesel-electric or LNG (liquefied natural gas) systems, which are more expensive upfront but cheaper long-term.

- Interior Fit-Out: Cabins, restaurants, theaters, pools, spas, and retail spaces. This is where luxury meets function. Think marble countertops, custom lighting, and soundproofing.

- Technology and Safety Systems: Navigation, communication, fire suppression, lifeboats, and emergency protocols. These are non-negotiable and heavily regulated.

- Labor and Engineering: Skilled welders, electricians, designers, naval architects, and project managers. Labor can account for 30–40% of total costs, especially in high-wage European shipyards.

<

Why It’s So Expensive

You might wonder: Why can’t we build them cheaper? The answer is simple: safety, regulations, and scale. Cruise ships must meet strict international standards from organizations like the International Maritime Organization (IMO) and classification societies like DNV or Lloyd’s Register. Every bolt, weld, and circuit is inspected. Plus, the materials must withstand saltwater corrosion, extreme weather, and decades of use.

For example, Royal Caribbean’s Icon of the Seas, launched in 2023, is the world’s largest cruise ship. It cost over $2 billion to build. That’s not a typo. But when you consider it has 20 decks, 2,800 staterooms, a 55-foot waterfall, and a 1,700-seat theater, the cost starts to make sense.

Breaking Down the Cost by Ship Size and Class

Not all cruise liners are created equal. The how much does a cruise liner cost to make question depends heavily on the ship’s size, class, and target market. Let’s explore the different tiers.

Small to Mid-Sized Ships (50,000–100,000 GT)

These are boutique vessels, often for luxury or expedition cruising. Think Seabourn, Silversea, or Lindblad Expeditions. They carry 500–2,000 passengers and focus on exclusivity.

- Cost Range: $400 million to $700 million

- Examples:

- Scenic Eclipse (2019): $185 million (expedition-focused, smaller GT)

- Silver Nova (2023): $600 million (luxury, 728 passengers)

- Why the Price? High-end finishes, smaller production runs, and advanced stabilization systems for rough seas.

Large Mainstream Ships (100,000–150,000 GT)

This is the sweet spot for most major cruise lines—Carnival, Norwegian, Princess. These ships carry 3,000–4,000 guests and offer a wide range of amenities.

- Cost Range: $800 million to $1.3 billion

- Examples:

- Carnival Celebration (2022): $1 billion

- Norwegian Prima (2022): $1.2 billion

- Why the Price? More cabins, larger entertainment venues, and advanced tech like hybrid power systems. Also, these ships are built in bulk, but still require custom features to stand out.

Mega-Ships (150,000+ GT)

These are the floating cities. They dominate headlines and carry 5,000–7,000 passengers. Think Royal Caribbean’s Oasis-class or Carnival’s Excel-class.

- Cost Range: $1.5 billion to $2.5 billion

- Examples:

- Wonder of the Seas (2022): $1.6 billion

- Icon of the Seas (2023): $2.1 billion (estimated)

- Carnival Jubilee (2023): $1.8 billion

- Why the Price? Scale drives cost, but so does innovation. Icon of the Seas has the first-ever onboard waterpark with six slides, a 1,200-person outdoor stage, and LNG propulsion. The sheer volume of materials and labor is astronomical.

Expedition and Niche Ships

These are small, specialized vessels for polar regions, river cruises, or private charters. They’re cheaper per ship but expensive per passenger.

- Cost Range: $100 million to $300 million

- Examples:

- Hurtigruten Expeditions’ MS Fridtjof Nansen (2019): $220 million

- Scenic Neptune (2022): $190 million (river cruise)

- Why the Price? Ice-class hulls, advanced navigation, and eco-friendly tech. These ships are built to last 30+ years in harsh conditions.

The Role of Shipyards and Location in Pricing

Where a cruise liner is built has a huge impact on the final cost. Labor rates, regulations, and supply chain access vary dramatically by region. This is a key factor in answering how much does a cruise liner cost to make.

European Shipyards: The Gold Standard

Europe—especially Finland, Germany, and Italy—is the epicenter of cruise ship construction. Why?

- Skilled Labor: Decades of experience in luxury and safety standards.

- High Wages: Unionized labor means higher costs, but also higher quality.

- Proximity to Suppliers: European suppliers provide everything from HVAC systems to furniture.

- Examples:

- Meyer Turku (Finland): Built Icon of the Seas and Wonder of the Seas

- Meyer Werft (Germany): Built Carnival Jubilee and Norwegian Prima

- Fincantieri (Italy): Built MSC World Europa and Princess Cruises’ Encore

But high quality comes at a price. A ship built in Europe can cost 20–30% more than one built in Asia, but it’s often worth it for safety and reliability.

Asian Shipyards: Rising Competitors

China and South Korea are entering the cruise ship market, offering lower labor costs and government incentives.

- Advantages:

- Lower labor costs (up to 40% cheaper than Europe)

- Government subsidies for shipbuilding

- Rapid construction timelines

- Challenges:

- Lack of experience with luxury cruise interiors

- Longer supply chains (many components still imported from Europe)

- Perception of lower quality (though improving)

- Examples:

- Chantiers de l’Atlantique (France) still dominates, but Shanghai Waigaoqiao Shipbuilding is building Carnival’s first China-made cruise ship (launching 2024).

Cost Comparison: Europe vs. Asia

Let’s say you’re building a 140,000 GT ship:

- Europe: $1.1 billion (higher labor, better quality, faster delivery)

- Asia: $850 million (lower labor, longer build time, potential delays)

The $250 million savings might sound great—but consider: European ships are delivered on time 85% of the time, while Asian shipyards average 70%. Delays can cost millions in lost revenue. So, while the upfront cost is lower in Asia, the total cost of ownership may be higher.

Hidden Costs You Might Not Think About

When people ask, how much does a cruise liner cost to make, they often focus on the sticker price. But the real cost goes far beyond the shipyard. Here are the hidden expenses that can add millions—or even billions—over a ship’s lifetime.

Regulatory Compliance and Certification

Before a ship can sail, it must pass rigorous inspections. This isn’t a one-time fee—it’s an ongoing process.

- Classification Society Fees: $5–10 million for initial certification and annual renewals.

- Safety Equipment: Lifeboats, life rafts, fire systems, and emergency generators can cost $20–30 million.

- Environmental Compliance: Scrubbers, ballast water treatment, and wastewater systems add $15–25 million.

For example, Carnival spent $300 million retrofitting its fleet with scrubbers to meet IMO 2020 sulfur regulations. That’s not part of the build cost—but it’s essential for operation.

Training and Crewing

A ship isn’t just metal and engines. It’s people. And people need training.

- Initial Crew Training: $5–10 million (safety drills, language skills, service standards)

- Ongoing Training: $2–5 million per year (refreshers, new tech, guest service)

- Crew Salaries and Benefits: $50–100 million per year for a large ship (1,500+ crew members)

Remember: the crew lives onboard for months at a time. That means food, housing, medical care, and mental health support—all included in operating costs.

Technology Upgrades and Retrofits

Technology moves fast. A ship built today might be outdated in 5–10 years.

- Wi-Fi and Connectivity: $5–10 million (satellite systems, bandwidth)

- Entertainment Systems: $3–8 million (theaters, VR zones, sound systems)

- Energy Efficiency Upgrades: $10–20 million (LED lighting, smart HVAC, solar panels)

Royal Caribbean’s Harmony of the Seas spent $20 million upgrading its Wi-Fi system after guests complained about poor connectivity. That’s not a build cost—but it’s a real expense.

Insurance and Risk Management

Insuring a $2 billion floating city isn’t cheap.

- Hull and Machinery Insurance: 0.5–1% of ship value per year → $10–20 million/year

- Liability Insurance: $5–10 million/year (covers accidents, medical emergencies)

- Business Interruption Insurance: $2–5 million/year (in case of delays or cancellations)

And don’t forget: if a ship is delayed, the cruise line loses millions in ticket sales. So, insurers often require higher premiums for ships under construction.

Real-World Examples: Case Studies of Cruise Liner Costs

Let’s look at three real ships to see how the numbers add up. These examples show the full picture behind how much does a cruise liner cost to make.

Case Study 1: Icon of the Seas (Royal Caribbean, 2023)

- Cost: $2.1 billion

- Size: 250,800 GT, 5,610 passengers

- Key Features:

- 8 distinct neighborhoods

- 6 record-breaking water slides

- First LNG-powered Royal Caribbean ship

- 1,700-seat outdoor stage

- Cost Breakdown:

- Hull and Structure: $500 million

- Propulsion (LNG): $200 million

- Interior Fit-Out: $600 million

- Entertainment: $150 million

- Technology and Safety: $300 million

- Labor and Project Management: $350 million

Fun fact: The ship’s central park has 20,000 real plants. That’s not just landscaping—it’s a living ecosystem that needs constant care.

Case Study 2: MSC World Europa (MSC Cruises, 2022)

- Cost: $1.4 billion

- Size: 215,863 GT, 6,762 passengers

- Key Features:

- World’s largest LNG-powered cruise ship

- 13 restaurants, 21 bars

- 1,100-seat theater

- Advanced wastewater treatment

- Cost Breakdown:

- Hull and Structure: $350 million

- LNG Propulsion: $250 million

- Interior Fit-Out: $400 million

- Environmental Systems: $150 million

- Technology: $100 million

- Labor: $150 million

MSC saved costs by using a modular construction method—building sections in different shipyards and assembling them in France.

Case Study 3: Silver Nova (Silversea, 2023)

- Cost: $600 million

- Size: 54,700 GT, 728 passengers

- Key Features:

- All-suite accommodations

- Hybrid propulsion (diesel + battery)

- Infinity pool with glass bottom

- Private butler service for all guests

- Cost Breakdown:

- Hull and Structure: $150 million

- Hybrid Propulsion: $80 million

- Interior Fit-Out: $250 million (luxury finishes, marble, custom furniture)

- Technology: $50 million

- Labor: $70 million

Despite its smaller size, Silver Nova has one of the highest cost-per-passenger ratios in the industry—$824,000 per guest. That’s the price of exclusivity.

Data Table: Cruise Liner Cost Comparison (2020–2024)

| Ship Name | Year | GT (Gross Tonnage) | Passengers | Cost (USD) | Cost per Passenger | Shipyard |

|---|---|---|---|---|---|---|

| Icon of the Seas | 2023 | 250,800 | 5,610 | $2.1 billion | $374,331 | Meyer Turku, Finland |

| MSC World Europa | 2022 | 215,863 | 6,762 | $1.4 billion | $207,039 | Chantiers de l’Atlantique, France |

| Norwegian Prima | 2022 | 142,500 | 3,215 | $1.2 billion | $373,250 | Meyer Werft, Germany |

| Silver Nova | 2023 | 54,700 | 728 | $600 million | $824,175 | Meyer Werft, Germany |

| Carnival Jubilee | 2023 | 183,000 | 6,630 | $1.8 billion | $271,493 | Meyer Werft, Germany |

| Scenic Eclipse | 2019 | 17,085 | 228 | $185 million | $811,403 | Uljanik Shipyard, Croatia |

Final Thoughts: The True Cost of a Floating City

So, how much does a cruise liner cost to make? The answer isn’t a single number. It’s a range—from $185 million for a boutique expedition ship to over $2 billion for a floating metropolis. But the cost isn’t just about dollars. It’s about value. Every dollar spent on safety, luxury, innovation, and sustainability pays off in guest satisfaction, brand loyalty, and long-term profitability.

When you’re on a cruise, you’re not just paying for a room and a buffet. You’re paying for the engineers who designed the hull, the welders who joined the steel, the chefs who trained the staff, and the environmental scientists who ensured the ship meets the highest standards. It’s a collective effort—one that takes years, millions of man-hours, and billions of dollars.

And here’s a tip for travelers: if you want to appreciate the cost behind your cruise, take a behind-the-scenes tour. Many ships offer galley tours, engine room visits, or meet-the-captain events. It’s a humbling reminder that behind every sunset cocktail is a floating city built with precision, passion, and a lot of hard work.

So next time you board a cruise liner, take a moment to look around. Feel the smooth deck under your feet. Hear the hum of the engines. Smell the fresh flowers in the lobby. And remember: this isn’t just a vacation. It’s the result of one of humanity’s most ambitious feats of engineering. And that, my friend, is worth every penny.

Frequently Asked Questions

How much does a cruise liner cost to build on average?

The average cost to build a cruise liner ranges from $500 million to over $1 billion, depending on size, luxury level, and onboard amenities. Larger ships like Royal Caribbean’s Oasis-class vessels can exceed $1.4 billion due to advanced technology and expanded capacity.

What factors influence the cost of a cruise liner?

Key factors include ship size, materials, propulsion systems, interior design, and compliance with international safety and environmental regulations. Custom features like water parks, theaters, and smart cabins can significantly drive up the final price tag.

How much does a cruise liner cost to make compared to a cargo ship?

A cruise liner typically costs 3–5 times more than a cargo ship of similar size due to luxury interiors, passenger amenities, and complex systems for comfort and entertainment. While a cargo ship may cost $200 million, a comparable-sized cruise ship could cost $800 million or more.

Are smaller cruise liners cheaper to construct?

Yes, smaller cruise liners (under 100,000 gross tons) generally cost between $300–$600 million, making them more affordable than mega-ships. However, per-cabin costs are often higher due to less economy of scale and specialized boutique designs.

How long does it take to build a cruise liner, and how does that affect cost?

Construction typically takes 2–4 years, with labor, engineering, and supply chain delays impacting the final cost. Extended timelines can add millions in overhead, especially if materials or technology require upgrades during the build.

Do cruise lines build their own ships or outsource?

Most cruise lines outsource construction to specialized shipyards like Meyer Werft (Germany) or Chantiers de l’Atlantique (France), which have the expertise and infrastructure. These shipyards use the cruise liner cost to make bids, factoring in labor, materials, and profit margins.